OVERVIEW:

A large hospital in Buffalo, NY, saved $946,141.00 in energy by implementing an aggressive coil cleaning program in their HVAC systems and upgrading the filtration using high technology filters from Clark Air Systems, Inc.

| Budgeted* annual electricity cost: | $2,252,500 |

| Actual annual electricity cost: | $1,650,947 |

| Electrical energy savings: | $601,553 |

| Savings are attributed to slower variable HVAC fan motors due to lower pressure drop on coil surfaces and filters. | |

|

|

|

| Budgeted* annual gas & oil cost: | $1,057,800 |

| Actual annual gas & oil cost: | $600,647 |

| Gas & Oil energy savings: | $457,153 |

| Savings are attributed to lower boiler/chiller loading due to better heat transfer efficiency on clean coil surfaces. | |

| Budgeted* annual electricity cost:

Actual annual electricity cost: Electrical energy savings: |

$2,252,500

$1,650,947 $601,553 |

Savings are attributed to slower variable HVAC fan motors due to lower pressure drop on coil surfaces and filters. |

|

|

||

| Budgeted* annual gas & oil cost:

Actual annual gas & oil cost: Gas & Oil energy savings: |

$1,057,800

$600,647 $457,153 |

Savings are attributed to lower boiler/chiller loading due to better heat transfer efficiency on clean coil surfaces. |

* Budgeted numbers were based on previous years’ actual usage.

Background:

- Three-year evaluation of filter products concluded with the selection of high technology filtration from Clark Air Systems, Inc.

- The keys to the selection of Clark Air Systems over the previous commodity filters:

- The energy performance of the filters – by operating at a much lower pressure drop, significant electrical energy savings can be realized.

- Longevity and life-cycle cost of the filters – high dirt capacity, microbial resistance, durability, and lower pressure drop allow the hospital to prolong the operational life of the installed filters.

- Non-shedding, non-fiberglass final filtration, elimination of cardboard in all prefiltration.

- Service, professionalism and expertise of the Clark Air Systems representative.

- As the filter upgrade was implemented, a complete unit-by-unit cleaning was conducted on all HVAC internal surfaces including a thorough cleaning of all heat transfer surfaces.

- Energy expenditures are taken directly from the Plant Operations Spectrum spreadsheets.

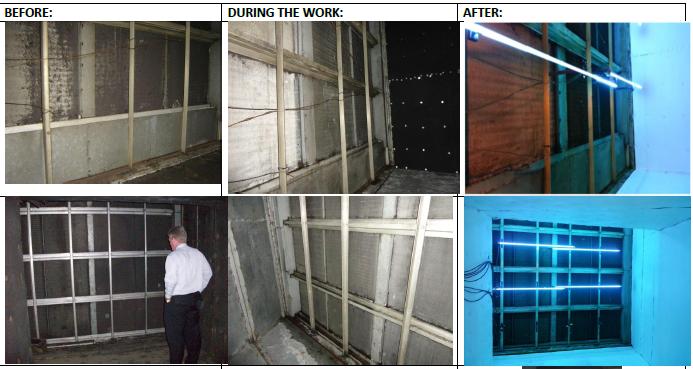

HVAC renovation with UV light system and Flex Seal coating

Location: Major Medical Center -Upstate NY

Units: Two circa 1970 HVAC systems

Clark Air Systems was asked to strip the old moldy, broken insulation, which had fallen into disrepair over forty years of service; install new insulation; physically clean the coils, and apply an ultraviolet coil sanitizer.

UV system: all lamp ballasts are outside the airstream tucked away in a NEMA 4 ballast box for easy service and safety.