Industrial Air Cleaners - Air Revolver

Clark Air Systems Air Revolver Industrial Air Cleaners

The industry’s best air cleaner system designed for:

- Heavy Industrial air cleaning

- Light Industrial air cleaning

- Schools with trade shops

- Welding shop air cleaning

- Body shops air cleaning

- Wood dusts

- Large bays

- Dirty environments

- Textile shops

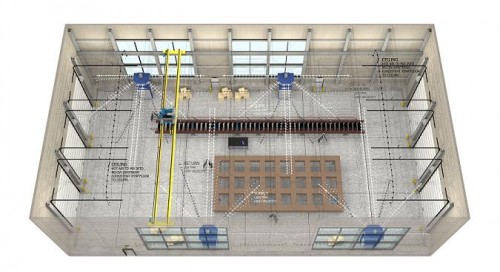

Application: General Industrial Air Cleaning, whole plant filtration systems using the air rotation concept for welding smoke, fabrication shops, auto collision dust, woodworking dust, refinishing shops and more.

The first general air cleaning system with an energy payback!

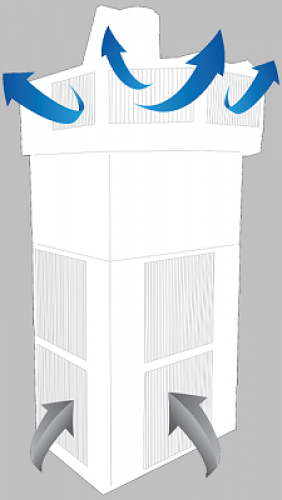

10 times more effective than overhead industrial air cleaners! Combines Downdraft and Air Revolver technologies to remove airborne particulates to 1 micron. The intake and outlet are designed for the most efficient air flow pattern in the industry. The return scoops air at the floor, pulling particulate in a downdraft pattern. The supply air is projected across the room with higher velocity to flood the room with pure air. All models are standard with high efficiency particulate filters, and optional carbon filters and variable speed fans. Model AR8000 and AR15000.

Features:

Forcibly controls ambient dust and pollutants

Multi-stage filtration—custom selected for any contaminant

Does not deteriorate to lethargic flow levels with usage

Powerful and uniform distribution of purified air

Non-observable airflow to occupants for comfort

De-stratify heat vertically, saving energy

Filter life extended 5 times over conventional systems

Patent pending

Specifications:

Airflow: up to 30,000 CFM Capacity

8,000 – 30,000 CFM design range

Small footprint

Height options of 11’ or 14’ depending on plant

Power: 3 phase 208-230/460 Volt

Multiple filter stages handle any contaminant situation

10 and 16 gage welded steel construction

Industrial enamel finish — Clark Air Blue

Easy two section installation

Five-year warranty available

Advantages:

Improved air quality will improve productivity and performance

Longer-life filter will reduce cost and lessen material disposal

Significant energy savings by de-stratification of heat layers, homogenizing the air from floor to ceiling to within 5 degrees

Showing all 2 results